Introduction to Carbon Black Masterbatch

- 1 1. What is Carbon Black Masterbatch?

- 2 2. Key performance advantages of Carbon Black Masterbatch

- 3 3. Application-specific insights using long-tail keyword focus

- 3.1 3.1 carbon black masterbatch for film extrusion

- 3.2 3.2 carbon black masterbatch with enhanced UV resistance

- 3.3 3.3 carbon black masterbatch for conductive plastic components

- 3.4 3.4 carbon black masterbatch dosage guidelines for pipes

- 3.5 3.5 carbon black masterbatch dispersion performance in HDPE

- 4 4. How to choose and optimise Carbon Black Masterbatch for best results

- 5 5. Company case: How we (Changzhou Runyi New Material Technology Co., Ltd.) deliver high-quality Carbon Black Masterbatch

- 6 6. Future trends and sustainability in Carbon Black Masterbatch

- 7 FAQ

The polymer and plastics industry continuously seeks materials that not only colour but also enhance performance. Among them, Carbon Black Masterbatch has emerged as a vital additive solution—merging deep black pigmentation with functional benefits. In this article, we will explore what it is, why it matters, how to use it across applications (including carbon black masterbatch for film extrusion and carbon black masterbatch with enhanced UV resistance), how to select and optimise it, and why our company, Changzhou Runyi New Material Technology Co., Ltd., stands out in delivering these solutions.

PP Hygienic/Food Grade EVA/ABS/PET Plastic Pellets Black Masterbatch

1. What is Carbon Black Masterbatch?

1.1 Definition and basic composition

- Carbon Black Masterbatch is a concentrated blend in which carbon black pigment is compounded into a carrier resin (typically PE, PP, PA or similar) along with additives for dispersion and stability.

- The carrier ensures better handling, improved dispersion and easier dosing compared to raw carbon black.

- Typical loading levels are in the range of about 15%-50% carbon black content depending on application.

1.2 Why it matters in modern plastics manufacturing

- Deep black colour ("jetness") is often required for aesthetic consistency across mouldings, films and extrusions.

- Beyond colour, carbon black in masterbatch contributes UV and weather resistance—especially important for outdoor or exposed products.

- In advanced applications, carbon black masterbatch may deliver conductive or antistatic properties when properly formulated.

2. Key performance advantages of Carbon Black Masterbatch

2.1 Colour strength and appearance consistency

- High tinting strength means less material can achieve deep black colour—helping cost optimisation.

- Good dispersion of carbon black ensures uniform appearance and avoids issues such as streaks or uneven shade.

2.2 UV- and weather-resistance benefits

- Carbon black acts as a UV-absorber and protects the polymer matrix from photodegradation.

- This is particularly beneficial in extruded products such as pipes, films, outdoor components.

2.3 Mechanical and conductive / antistatic enhancements

- When properly dispersed, carbon black contributes to enhanced tensile strength, impact resistance and durability of plastics.

- For conductive or antistatic applications, carbon black masterbatch can be a preferred route rather than raw pigment.

3. Application-specific insights using long-tail keyword focus

3.1 carbon black masterbatch for film extrusion

Film extrusion demands high dispersion and uniform colour across thin gauges. Using the correct carbon black masterbatch ensures that films are visually consistent and have the required UV protection.

3.2 carbon black masterbatch with enhanced UV resistance

For outdoor applications such as geosynthetics, automotive under-hood parts or outdoor housings, opting for masterbatch that emphasises UV stability is key.

3.3 carbon black masterbatch for conductive plastic components

In components requiring antistatic or conductive functionality (e.g., certain electronics housings, cable sheaths), selecting a masterbatch formulated for conductivity is vital.

3.4 carbon black masterbatch dosage guidelines for pipes

Pipes (water, gas, drainage) often require deep black colour plus weather/UV resistance. Here, dosage guidance is important to balance cost, processing and performance.

3.5 carbon black masterbatch dispersion performance in HDPE

When using HDPE as the carrier or as the base resin, the dispersion performance of the masterbatch becomes especially important to avoid mottling or processing issues.

4. How to choose and optimise Carbon Black Masterbatch for best results

4.1 Carrier resin compatibility and dispersion quality

- Select a carrier resin that is compatible with your base polymer (e.g., PP base polymer with PP carrier masterbatch).

- Ensure the masterbatch has been processed with proper dispersion equipment to minimise agglomerates.

4.2 Carbon black particle size, surface area and loading rate

- Smaller primary particle size → higher surface area → better UV/stability/colour strength, but may raise viscosity and processing energy.

- Loading rate must align with performance requirements—higher loadings increase jetness but may affect flow.

4.3 Dosage & processing conditions – comparison table

4.3.1 Table: Typical dosage, key properties & expected outcome

| Application | Typical masterbatch dosage | Key expected property |

| Film extrusion | 1–2 % of total resin | Uniform black colour, minimal streaking |

| Outdoor pipes / conduits | 2–4 % | UV resistance, deep black finish |

| Conductive components | 3–5 % (or as specified by resistivity target) | Antistatic/conductive performance |

5. Company case: How we (Changzhou Runyi New Material Technology Co., Ltd.) deliver high-quality Carbon Black Masterbatch

5.1 Company overview and capabilities

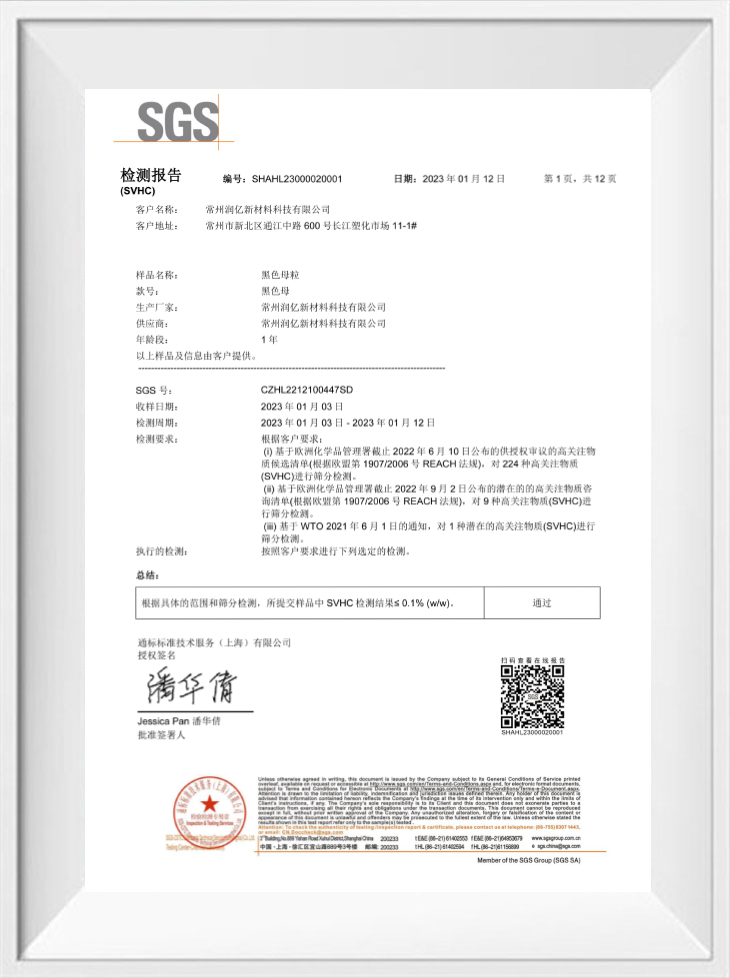

Founded in the Yangtze River Delta region, Changzhou Runyi New Material Technology Co., Ltd. has developed into a well-known colour masterbatch production and sales enterprise integrating research and development, production, sales, and export.

5.2 R&D, production lines & export structure

Starting from 2020, a research and development team for melt blown fabric projects was established, investing in multiple production lines for melt blown fabric black masterbatch, oil electret masterbatch, fluorocarbon polymer electret masterbatch, and water electret masterbatch. Our company's carbon black products and electrodes are produced according to international standards.

5.3 Commitment to energy savings, environmental protection & quality

We are committed to technological innovation, energy conservation, and sustainable development, establishing long-term cooperative relationships with numerous enterprises worldwide.

6. Future trends and sustainability in Carbon Black Masterbatch

6.1 Recycled carbon blacks & circular economy

The plastic industry is increasingly emphasising sustainability. Recovered or recycled carbon black (rCB) is rising in importance, allowing reuse of materials and reducing environmental footprint.

6.2 High-performance functional masterbatches (UV, conductive, flame retardant)

As performance demands rise, masterbatches with additional functions—such as heightened UV resistance, conductive pathways or flame retardancy—are becoming more prevalent.

FAQ

- What is the difference between colour masterbatch and Carbon Black Masterbatch?

Colour masterbatch refers broadly to masterbatches for colouration in plastics; Carbon Black Masterbatch is a specific type using carbon black pigment to impart deep black colour plus functional properties such as UV protection and conductivity. - How do I determine the correct dosage of Carbon Black Masterbatch for my extrusion application?

Dosage depends on application type, base resin, desired colour depth and functional requirements. For example, film extrusion may use about 1-2%, outdoor pipes 2-4%. - Why is dispersion so important for Carbon Black Masterbatch?

Poor dispersion leads to agglomerates, uneven colour, streaking, and reduced performance. A well-dispersed masterbatch ensures uniform appearance and optimal results. - Can Carbon Black Masterbatch also deliver conductive or antistatic properties?

Yes. When formulated with conductive-grade carbon blacks and compatible carriers, it can be used for antistatic or conductive plastic components. - What sustainability trends should I watch in the Carbon Black Masterbatch field?

Trends include use of recycled carbon black (rCB), bio-based carriers, and multi-functional masterbatches combining UV protection, conductivity, and flame retardancy.

prevNo previous article

nextWhat to Do When Fiber Breakage or Spinning Abnormalities Occur While Using Meltblown Masterbatch?

English

English 中文简体

中文简体 한국어

한국어 عربى

عربى