Non-Woven/Polypropylene Fiber/Yarn Multicolor Color Masterbatch

Multi-color masterbatch for non-woven fabrics, polypropylene and yarn is a type of color pigment particles specially designed for these textiles. Due to its coloring properties, it is often used in home decoration, medical and health care. Non-woven multi-color masterbatch, with its uniform dispersion and high stability, makes non-woven products bright and durable. Yarn multi-color masterbatch focuses on the fineness of yarn and the uniformity of color to ensure that the color is not easy to fall off or fade during the textile process.

Description

Color masterbatch is a highly concentrated color particle made by mixing resin raw materials with pigment additives and then granulating.

With good quality stability, dispersion, quality assurance, can be used directly with mixed resin, does not pollute the container, easy to change color. Monochrome and full concentration disperse pigments. It is easy to adjust the color, and it is made of organic pigments inorganic pigments, and auxiliaries. According to the different color requirements of customers to adjust the size of monofilm, light resistance, temperature resistance, and other performance requirements of color masterbatch.

Add ratio: 2%~4%

Non-Woven/Polypropylene Fiber/Yarn Multicolor Color Masterbatch is a high-performance concentrated masterbatch designed for the coloring needs of polymer materials. The product uses high-purity polypropylene as a carrier, selects high-temperature resistant organic/inorganic pigments, and achieves color uniformity (ΔE≤0.5) through nano-level dispersion technology, which can accurately match Pantone color cards and customized color systems.

Technical advantages:

High efficiency and compatibility: Suitable for PP spunbond, meltblown and other non-woven fabric processes (processing temperature 230-280℃), without affecting fiber strength (breaking strength retention rate ≥98%);

Multi-color performance: A single batch of masterbatch can compound 3-5 color particles to achieve gradient/mixed color effects and meet differentiated terminal needs (such as medical protective products and fashionable packaging materials);

Excellent stability: Passed ISO9001 quality system certification, migration resistance reached level 4 or above, and color difference change ≤1.5 levels after UV aging test (300h);

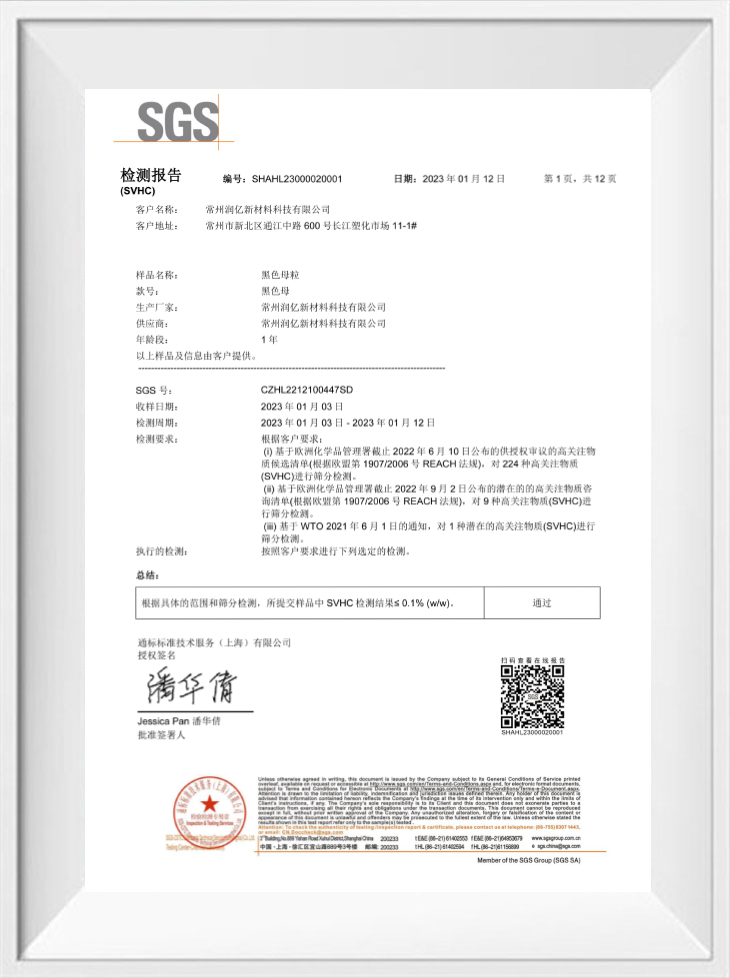

Environmental compliance: Comply with REACH and FDA standards, heavy metal content is less than 0.001%, suitable for sanitary materials and food contact products.

Widely used in medical protection, home decoration, industrial textiles and other fields, helping customers reduce 5-15% coloring costs and increase product premium space.

Get in Touch With Us

Who Are We?

Changzhou Runyi New Material Technology Co., Ltd.

News

-

Conductive vs. Pigment-Grade: Technical Analysis ...

In the high-stakes world of polymer engineering, choosing the right carbon black master batch is not merely a matte...

READ MORE -

Can Choosing a High-Concentration Carbon Black Ma...

In the competitive landscape of polymer processing, the selection of additives is a critical determinant of both pr...

READ MORE -

How Does Carbon Black Concentration in plastic bl...

In the precision world of polymer engineering, plastic black masterbatch serves as much more than a simple colorant...

READ MORE -

How Does Carbon Black Master Batch Dispersion Qua...

In the global infrastructure sector, High-Density Polyethylene (HDPE) pipes are the preferred medium for water, gas...

READ MORE -

How to Ensure Optimal Dispersion and Tinting Stre...

In the precision-driven world of polymer processing, achieving a flawless finish and consistent color performance d...

READ MORE

English

English 中文简体

中文简体 한국어

한국어 عربى

عربى