Polymer Base Masterbatch Manufacturers

information to be updated

Product Category

Get in Touch With Us

Who Are We?

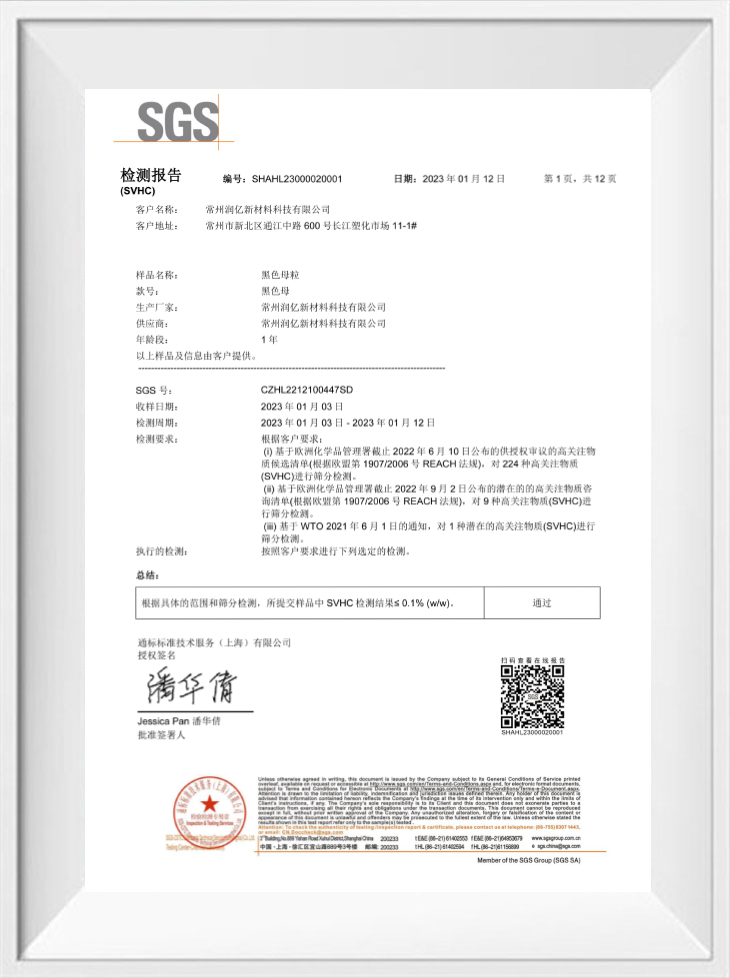

Changzhou Runyi New Material Technology Co., Ltd.

News

-

Conductive vs. Pigment-Grade: Technical Analysis of Car...

In the high-stakes world of polymer engineering, choosing the right carbon black master batch is not merely a matter of color. It is a decision based on the spe...

READ MORE -

Can Choosing a High-Concentration Carbon Black Masterba...

In the competitive landscape of polymer processing, the selection of additives is a critical determinant of both product quality and operational expenditure. Fo...

READ MORE -

How Does Carbon Black Concentration in plastic black ma...

In the precision world of polymer engineering, plastic black masterbatch serves as much more than a simple colorant. For B2B manufacturers and injection molders...

READ MORE -

How Does Carbon Black Master Batch Dispersion Quality A...

In the global infrastructure sector, High-Density Polyethylene (HDPE) pipes are the preferred medium for water, gas, and telecommunications. However, when these...

READ MORE

Color Masterbatch Industry Knowledge Extension

How to improve the performance and color stability of plastic products through polymer masterbatch?

Polymer Base Masterbatch is a key material for plastic modification and is widely used to improve the mechanical properties, weather resistance, color performance and functionality of plastic products. The following analyzes the application strategy and technical points of masterbatch from the two major directions of performance optimization and color stability.

1. Key masterbatch technology to improve the performance of plastic products

1. Functional masterbatch enhances physical and chemical properties

Mechanical property optimization:

Add glass fiber reinforced masterbatch to improve tensile strength, rigidity and impact resistance (applicable to automotive parts and electronic housings).

Use elastomer modified masterbatch (such as TPE, POE) to improve flexibility and brittle crack resistance (such as packaging film, hose).

Weather resistance and anti-aging:

Anti-UV masterbatch (containing light stabilizers such as HALS, UV absorbers) delays yellowing and degradation of outdoor products (such as building materials, outdoor furniture).

Anti-oxidant masterbatch (phenols, phosphites) prevents oxidative degradation during high temperature processing.

Flame retardant and safety performance:

Halogen-free flame retardant masterbatch (such as aluminum hydroxide, phosphorus flame retardant) meets the fire protection standards of electronic appliances and automotive materials (such as UL94 V0).

2. Processing performance optimization

Lubricating dispersing masterbatch: improve melt fluidity and reduce screw wear (suitable for high-filling systems such as calcium carbonate masterbatch).

Antistatic masterbatch (containing conductive carbon black or permanent antistatic agent) prevents dust adsorption (such as electronic packaging, medical equipment).

2. Masterbatch application scheme to ensure color stability

1. Key technologies of masterbatch

Selection of highly dispersible pigments:

Organic pigments (such as phthalocyanine blue and azo red) are brightly colored, but the dispersion process needs to be optimized to avoid agglomeration.

Inorganic pigments (such as titanium dioxide and iron oxide) have good temperature resistance and are suitable for high-temperature processing (such as engineering plastics).

Carrier resin matching:

Select a carrier that is compatible with the substrate (such as PP-based masterbatch for PP products) to avoid color difference or precipitation due to poor compatibility.

2. Solve the color stability problem

Migration resistance:

Use highly weather-resistant pigments (such as quinacridone) or surface treatment technology to prevent color migration to the surface of the product.

Heat/light aging resistance:

Add light stabilizers (such as hindered amine HALS) and heat stabilizers to prevent fading after long-term use (such as automotive interiors, outdoor signs).

Batch consistency control:

Strictly control pigment concentration and dispersion process (such as twin-screw extrusion shear optimization) to ensure color reproducibility.

3. Industry application cases

Packaging industry: transparent PP masterbatch + anti-UV agent to extend the life of food packaging film.

Automotive parts: Black ABS masterbatch (containing carbon black) takes into account both color depth and scratch resistance.

Electronic appliances: PC/ABS flame retardant masterbatch + customized masterbatch to meet appearance and safety requirements.

English

English 中文简体

中文简体 한국어

한국어 عربى

عربى